Aiguille du Midi Architectural Engineering Secrets

Explore Aiguille du Midi architectural engineering in 2025. Discover how builders conquered high-altitude challenges in Chamonix today!

On this page

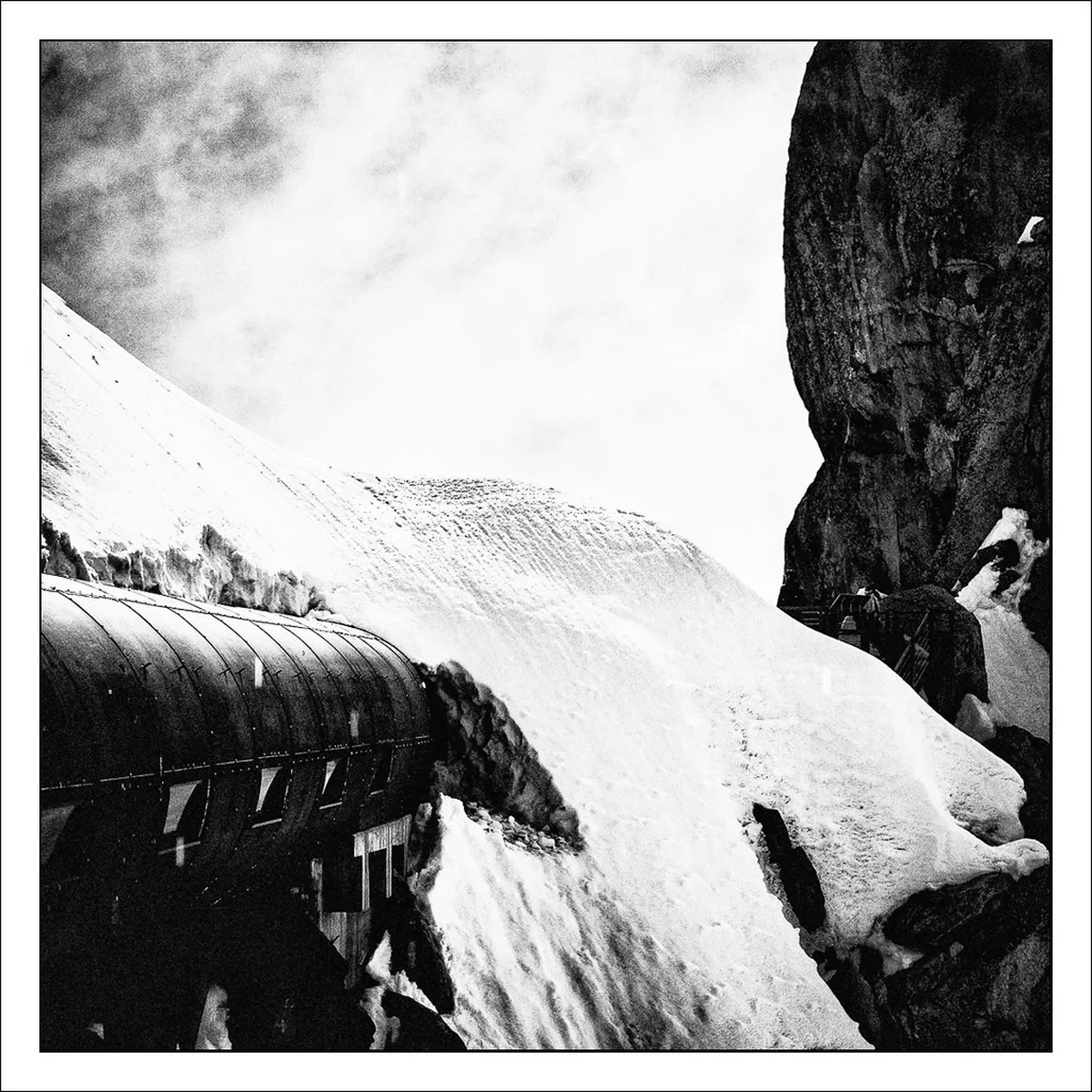

Aiguille du Midi architectural engineering represents a peak of human achievement in the French Alps. Located in Chamonix, this massive structure sits atop a jagged granite peak near Mont Blanc. Engineers faced extreme conditions during the early construction of this world-famous mountain site. Visitors in 2025 can still marvel at these incredible feats of design and strength.

The surrounding area features a wide variety of impressive architecture in Chamonix for tourists. The journey starts with a cable car ride that ascends over two thousand vertical meters. This vertical climb offers views of the complex engineering used to build the station. Understanding the technical side of the building enhances the overall visitor experience today.

Origins of Aiguille du Midi Architectural Engineering

The original construction plan for the station began in the early twentieth century. However, the most significant work occurred during the mid-fifties with very limited technology. Engineers had to design systems that could operate in nearly impossible Alpine conditions. You can read the full Aiguille du Midi 1955 station history for more deep details.

Workers lived in small wooden shacks perched on the edge of the snowy cliffs. They relied on physical strength and basic pulley systems to move heavy steel beams. The thin air at this altitude made every task twice as difficult for them. Despite these hardships, the team completed the first main station in record time.

The design focused on stability and resistance to the powerful forces of mountain nature. Strong cables were used to bridge the gaps between the high granite peaks. This early engineering paved the way for modern mountain construction techniques worldwide. Tourists now benefit from the bravery and skill of those early twentieth-century builders.

Maintaining the original vision requires constant monitoring of the site's structural integrity. Engineers use modern sensors to track any shifts in the rock or metal components. The legacy of the 1955 project continues to inspire architects and mountain climbers. Aiguille du Midi stands as a testament to the power of human will and design.

Extreme High-Altitude Building Challenges

High-altitude environments present a unique set of high-altitude building challenges for modern construction teams. Extreme cold causes metals to contract and become brittle in the winter months. Winds at the summit can reach speeds of over two hundred kilometers per hour. These forces require every part of the building to be bolted firmly into rock.

Logistics also play a major role in the success of any high-altitude building project. Everything from cement to drinking water must be transported by cable car or helicopter. The limited space on the summit prevents the use of traditional large construction cranes. Builders must instead use specialized tools that are light enough for small teams.

The short summer season provides the only window for major structural repair work. Sudden storms can halt operations for days or even weeks at a time. Workers must be trained in both construction skills and high-altitude survival techniques. This combination of skills ensures that the station remains safe for all visitors.

Planning for these risks involves complex computer models and years of careful study. Engineers analyze the granite for any signs of cracks or potential rock slides. The safety of thousands of tourists depends on the accuracy of these technical studies. Modern technology helps builders overcome the hurdles of this unforgiving mountain landscape.

Structural Anchoring into Alpine Granite

Anchoring the station into the granite was the most critical step of the project. Engineers used diamond-tipped drills to create deep holes into the very hard rock. Large steel rods were then inserted and bonded with specialized industrial epoxy resins. This process creates a bond that can support the massive weight of the structures.

The granite of the Mont Blanc massif is known for its incredible density. This quality makes it an ideal foundation for such a large vertical building. However, drilling through this rock is an exhausting and time-consuming process for workers. The team had to replace their drill bits frequently due to the extreme hardness.

Every platform at the site is supported by a series of these deep anchors. The tension in the rods is checked regularly to ensure they remain perfectly tight. Rust prevention is also a major concern due to the constant moisture and snow. Special coatings are applied to all metal parts to prolong their functional lifespan.

The result is a structure that feels solid even during the strongest mountain storms. Visitors can walk across the metal bridges with total confidence in their structural safety. The engineering behind these anchors is hidden but vital for the station's existence. It allows the building to cling to the side of a nearly vertical cliff.

Step into the Void Glass Innovation

The Step into the Void glass construction is a masterpiece of modern transparent engineering. It consists of five thick layers of glass bonded together for maximum strength. The structure can support weights much higher than the average group of tourists. Engineers designed the glass to withstand temperature changes and high-speed mountain winds.

Special metal brackets hold the glass box over a drop of one thousand meters. These brackets are bolted directly into the rock using the same anchoring techniques. The glass is treated with an anti-reflective coating to improve the view for visitors. Maintenance teams clean the glass daily to ensure the experience remains crystal clear.

Walking onto the glass requires guests to wear special slippers to prevent any scratches. Even a small scratch could compromise the structural integrity of the outer glass layer. The feeling of standing over the abyss is made possible by this clever design. It has become the most popular feature of the entire Aiguille du Midi complex.

The engineering team spent years testing the box before it opened to the public. They used sandbags to simulate the weight of several people standing on the glass. These tests proved that the glass could handle even the most extreme tourist loads. Today, it remains a safe and thrilling highlight for every visitor to Chamonix.

Modern Logistics and Cable Car Support

Moving materials to the summit involves a complex system of cables and heavy pulleys. The cable car acts as the primary lifeline for all supplies and construction gear. During major repairs, specialized cargo cabins are used to lift heavy steel components. This logistics chain must be timed perfectly to avoid the busiest tourist hours.

Helicopters provide a faster alternative for light loads and emergency transport needs. However, flying at this altitude is dangerous due to thin air and unpredictable winds. Pilots must be highly skilled to hover near the sharp granite peaks of the mountain. Most heavy building projects still rely on the reliability of the mechanical cable system.

The storage of materials on the summit is limited by the very small platforms. Engineers must plan their deliveries to match the daily progress of the building crews. Any delay in the logistics chain can cause the entire project to stop. This requires constant communication between the valley floor and the high-altitude station.

Modern logistics software helps managers track every piece of gear sent up the mountain. This technology ensures that no resources are wasted during the short working season. The efficiency of these systems is vital for maintaining such a complex Alpine site. Even small items like screws and bolts must be carefully accounted for at altitude.

Sustainable Mountain Construction in Chamonix

Sustainable mountain construction focuses on reducing the environmental impact of these large structures. Planners in Chamonix now use eco-friendly materials that blend better with the rock. Solar panels have been installed on some surfaces to generate clean mountain energy. These efforts help protect the fragile Alpine ecosystem for future generations of visitors.

Waste management is another critical part of maintaining a sustainable high-altitude station. All trash must be carefully sorted and sent back down the mountain for recycling. Water systems are designed to minimize usage and prevent any leaks into the ground. These small steps contribute to a much larger goal of environmental preservation.

Architects are also looking at ways to make the buildings more energy efficient. New insulation materials help keep the interiors warm without using too much power. The goal is to create a station that is both functional and green. Future expansions will likely follow these strict sustainability guidelines to protect the Alps.

Visiting the site in 2025 shows the progress made in eco-friendly building techniques. The balance between human engineering and nature is better today than ever before. Engineers continue to search for new ways to reduce the carbon footprint of the spire. This commitment ensures that Aiguille du Midi remains a model for the entire world.

Frequently Asked Questions

What makes Aiguille du Midi architectural engineering unique?

The station is built on a narrow granite spire at high altitude. Engineers had to anchor the structure into rock using very deep steel rods. It remains one of the highest construction projects ever completed in Europe. This unique location requires constant monitoring and high-tech maintenance every year.

How was the Step into the Void constructed?

Builders used five layers of glass bonded with a strong transparent adhesive. The glass box hangs over a massive drop of one thousand meters. Steel brackets hold the box firmly to the side of the main building. The project required precise engineering to ensure the safety of every visitor.

What are the costs to visit the site in 2025?

A round trip for an adult costs about seventy-eight Euros in 2025. Prices may vary slightly depending on the season and any special events. Booking your tickets online in advance is recommended to avoid the long queues. Children and groups often receive a discount on the standard ticket price.

Is the engineering safe for all visitors?

The site follows strict safety rules and undergoes regular structural inspections. Designers built the platforms to handle heavy snow and very strong winds. You can find similar safety standards in high-altitude refuges design throughout the French Alps. Maintenance crews work throughout the year to keep the facility in top condition.

Aiguille du Midi architectural engineering is a true marvel of the modern world. It combines mid-century bravery with the latest in glass and metal technology. A visit in 2025 offers a unique look at how humans conquer the mountains. Plan your trip to Chamonix soon to see this engineering masterpiece in person.

The site continues to inspire new generations of architects and structural engineers. The surrounding area also offers a great Chamonix architecture walking tour for history fans. Whether you love engineering or mountain views, this location has something special. Experience the height of Alpine design at the summit of the Aiguille du Midi.

Key Takeaways

- Construction at 3,842 meters requires anchoring into dense granite.

- The Step into the Void uses five-layer glass for total safety.

- Logistics rely on heavy cable car systems and skilled helicopter pilots.

- Modern updates in 2025 focus on environmental sustainability and energy efficiency.

Related reads: architecturebycity.com.